Continental CombineMaster and CombineMaster VF tyres can now be specified with ContiPressureCheck, a unique tyre monitoring system that will help to prevent downtime this harvest.

ContiPressureCheck monitors the pressure and temperature of tyres. Sensors in the tyre communicate the pressure and the heat build-up to help the operator decide on the optimum operating pressure. There are two warning levels offered by the sensor. The first suggests that a fault has occurred, but the machine can continue to work. The second calls for an immediate stop due to a more severe tyre problem.

“This is a good way to improve the life of combine tyres and reduce unnecessary downtime. Operators can choose to have a handheld device, or a terminal mounted in the cab. Both will feed back information on the tyre and help the operator to make adjustments that will reduce the likelihood of tyre failure,” explains Continental agricultural tyre specialist Rebecca Shedden.

Provides tyre data

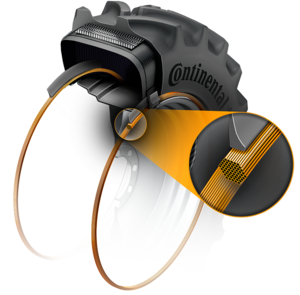

The most sensitive part of a tyre is the valve. ContiPressureCheck provides tyre data without the need to touch the valve. It therefore offers a safer and more secure way to monitor tyres and reduces the likelihood of dirt affecting the valve.

The new CombineMaster tyre has a unique Hexa bead construction that is safer on the road and reduces soil compaction in the field.

Miss Shedden explains that many tyres are replaced before the tread has worn fully. This is due largely to unknown tyre damage which leads to failure during use. “ContiPressureCheck is constantly monitoring tyre performance in real time and providing data to the operator. This helps to prevent downtime because the tyre will not be under undue stress and any fault in the tyre will be reported in time for the operator to make repairs or adjustments.”

The monitors can be retrofitted or purchased with the new generation of Continental agricultural tyres. “Continental has been manufacturing new tyres at a facility in Lousado, Portugal since 2017. These tyres are all covered by a 10-year warranty and designed to work with ContiPressureCheck, which can be specified when purchasing tyres or added retrospectively to extend tyre life and improve operational efficiency,” she concludes.